For immediate release

Across Europe, small and medium-sized manufacturers are redefining what’s possible in advanced composite engineering, thanks to the EU-funded DiMAT project. Now companies like ACCELIGENCE Ltd (unmanned aerial vehicles developer in Cyprus), CETMA (a leading Italian RTO www.cetma.it) and Cetma Composites Srl (Italian advanced composite manufacturer) are gaining access to digital manufacturing capabilities once the preserve of aerospace giants, enabling them to design lighter, greener and more efficient unmanned aerial vehicles (UAVs) at unprecedented speed.

Their collaborative pilot within DiMAT is now demonstrating how digital twins, simulation tools and renewable composite materials can transform UAV development for SMEs.

Opening up high-end composite optimisation to SMEs

High-performance composite UAV structures typically require expensive design tools, specialist modelling knowledge and lengthy testing cycles. For SMEs, this has traditionally meant limited innovation potential and long development timelines.

DiMAT changes all that.

Through its open digital toolbox, which includes, among others, the Materials Designer, Materials Modeller, Materials Processing Simulator and Digital Twin for Process Control, smaller composite manufacturers can now:

· Simulate composite behaviour before manufacturing

· Optimise material compositions based on real performance needs

· Tune process parameters digitally rather than by trial-and-error

· Integrate data seamlessly across materials, design and production

These capabilities dramatically lower entry barriers for SMEs wanting to compete in advanced composites and aerospace technology – and ACCELIGENCE and Cetma Composites are showing how it can be done.

Accelerating R&D from lab to prototype

The pilot the two companies are working on in the project is already showcasing how digital simulation replaces time-consuming physical testing. Using DiMAT’s Simulation & Optimisation Suite, they are showcasing how they can:

· Predict structural behaviour (strength, stiffness, load response)

· Simulate composite layups, curing cycles and process deviations

· Identify defects or design weaknesses early

· Cut down on the number of physical prototypes needed

This can dramatically shorten R&D timelines from months to weeks, making innovation faster, cheaper and more reliable. For UAV development, where weight, durability and performance must be perfectly balanced, this accelerated workflow is a major competitive advantage.

Greening drone manufacturing with renewable and recyclable composites

Beyond speed and affordability, ACCELIGENCE and Cetma Composites are also pioneering sustainability in UAV manufacturing by testing renewable and recyclable materials for structural components in their joint pilot study, analysing:

· Mechanical performance with DiMAT sub-models

· Manufacturing viability through digital process simulation

· Lifecycle cost and environmental impact via DiMAT’s MEC-LCA module

This enables data-driven decisions about material selection and production processes, ensuring UAV structures can be both lightweight and environmentally responsible.

This ACCELIGENCE and Cetma Composites pilot is one of four industrial testbeds demonstrating the power and versatility of the DiMAT Digital Toolkit across different manufacturing sectors. What makes this pilot particularly compelling is how clearly it shows the transformative potential for SMEs of this approach. Through DiMAT, they can now engage in advanced composite design with the same sophistication once reserved for major aerospace players.

Digital-twin technologies and high-fidelity simulation drastically shorten development cycles, enabling UAV concepts to move from design to validation far more quickly. At the same time, the use of renewable and recyclable composite materials becomes far less risky, thanks to lifecycle-aware modelling that anticipates performance and environmental impact before any physical manufacturing takes place.

Together, these capabilities reveal how data-driven optimisation can enhance both product performance and production efficiency. And while UAVs provide the immediate testing ground, the implications extend much further. The breakthroughs achieved in this pilot point towards wide-reaching impacts across composites manufacturing, lightweight mobility solutions, and Europe’s broader shift toward greener, more agile industrial processes.

NOTES

About the Pilot

The pilot investigates:

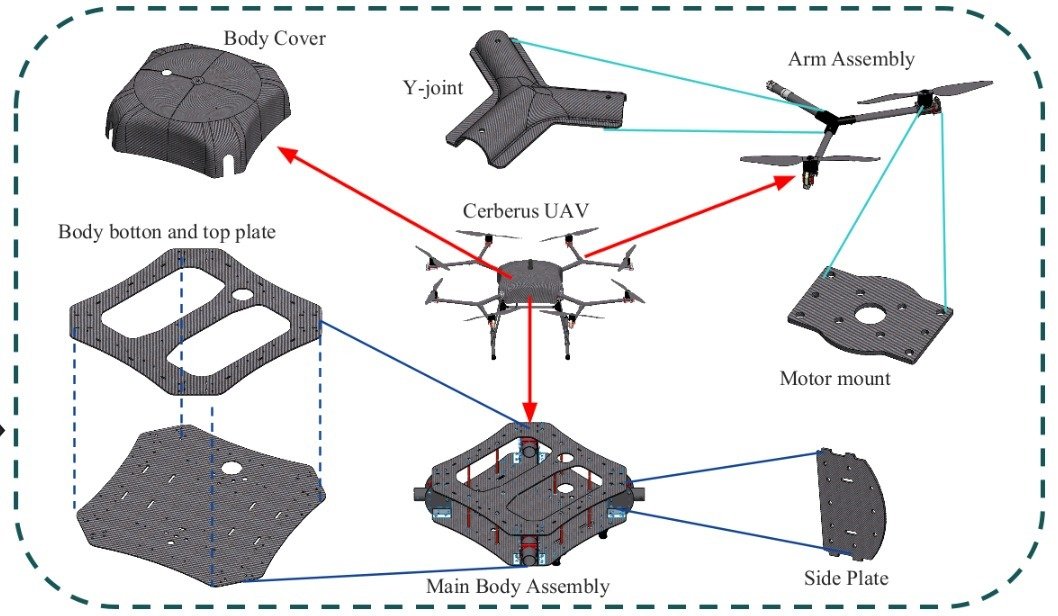

· Design of structural UAV components using advanced composites

· Use of renewable/recyclable composite materials

· Validation through prototyping, performance testing and lifecycle assessment

DiMAT’s integrated digital environment enables seamless iteration from materials design to final manufacturing evaluation.

About ACCELIGENCE

ACCELIGENCE Ltd is an innovative UAV developer based in Cyprus, focused on lightweight, high-performance aerial systems for industrial applications. With expertise in advanced composite structures and aerodynamic design, the company creates drones built for endurance, reliability and precision. Through the DiMAT pilot, ACCELIGENCE is adopting digital-twin and simulation tools to speed up structural optimisation, reduce prototyping time and explore new sustainable composite materials, strengthening its ability to innovate quickly and competitively.

About Cetma Composites

Cetma Composites Srl, a spin-off of the Italian research centre Consorzio CETMA is based in Italy. The company specialises in advanced composite materials and lightweight structural components for aerospace and mobility applications. Its work spans fibre-reinforced materials, process optimisation and high-quality composite manufacturing. As part of the DiMAT pilot, Cetma Composites is using the results of the project’s modelling and simulation tools to test renewable and recyclable composites, assess performance digitally and cut down on physical testing, enabling cleaner, faster and more efficient composite development.

About DiMAT

DiMAT is an EU-funded project creating an accessible, affordable digital ecosystem for modelling, simulating and optimising materials and manufacturing processes. It aims to provide SMEs and mid-caps with tools that accelerate innovation across the entire materials value chain.

More information

https://dimat-project.eu/

https://dimat-project.eu/

Press contacts

Ellie Shtereva, DiMAT Project

Ellie Shtereva, DiMAT Project

Sara Canedo, DiMAT Project